1. The Fabric

Your shirt’s fabric is next to your skin all day, so how that fabric feels is a crucial element of the shirt’s design. Thomas Pink sources its Egyptian cotton from Giza, our Supima cotton from California and our Sea Island cotton from the Caribbean. We select our mills carefully ensuring that these long-staple cottons are woven into durable fabrics with the finest quality. The result is breathable fabrics with a soft handle which feel luxurious against the skin, and which carry colour longer for a crisper, sharper look.

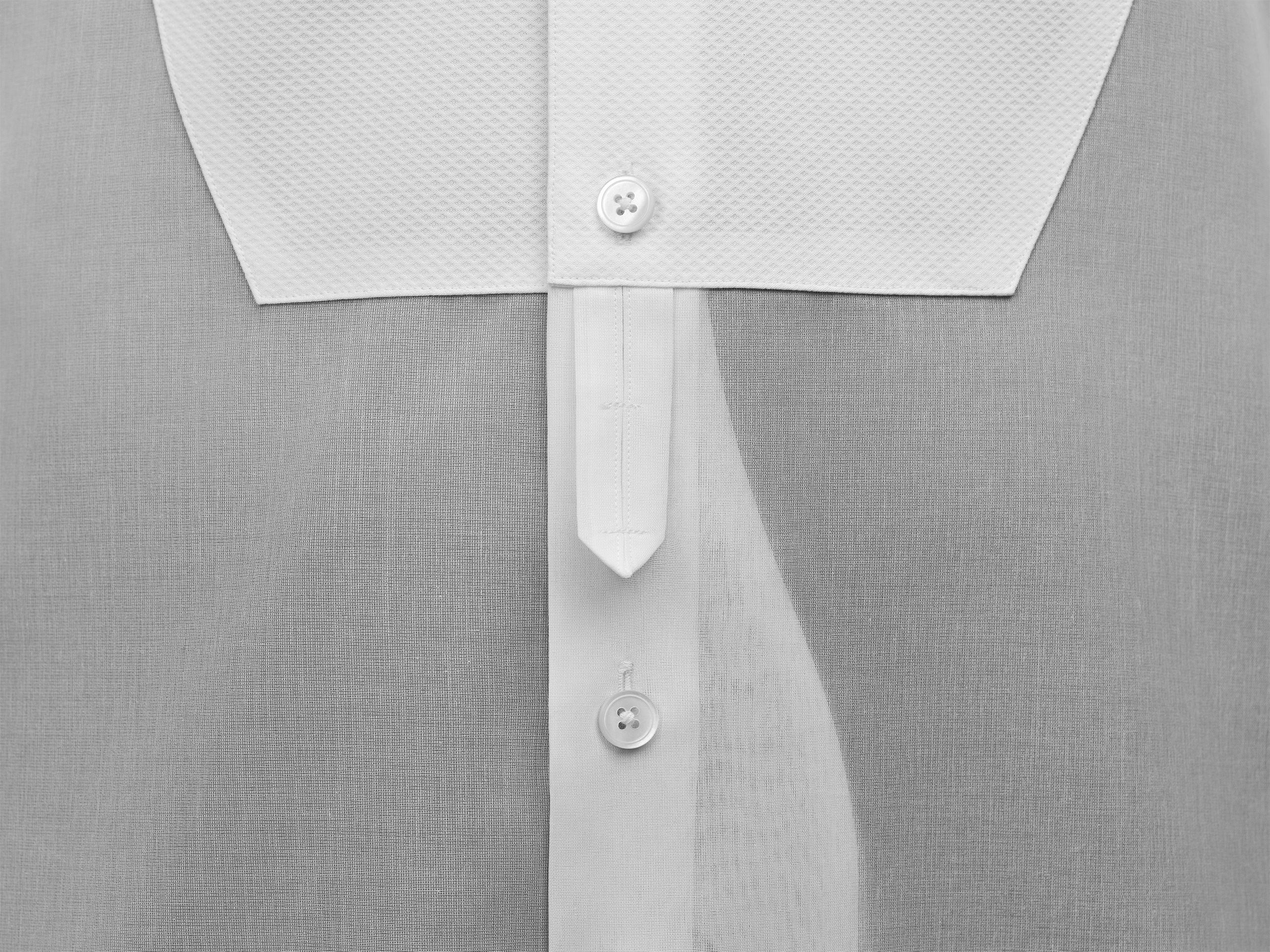

2. The Collar

Thomas Pink uses unfused collars with a floating interlining, a complex construction which makes the collar more durable. Our unfused collars contain 10 pattern pieces. These pieces are mostly invisible, but you’ll feel the benefits immediately. The collars improve with age gradually moulding to the shape of the neck. And will always sit with a ‘roll’ like the crest of a wave. Of course, we are not afraid of change when innovation requires it. So, for our Athletic shirts we use fused collars as these work better with stretch fabric.

3. The Cuff

They spend much of their time beneath suit sleeves, but cuffs face a lot of wear and tear. At Thomas Pink we make our cuffs with a fused interlining which helps keep them hard wearing and easy to iron. But what really separates them, is their recognisable barrel shape and unfussy single button fastening. You will always know when you see one.

4. The 1920's Panel

In the 1920s, many shirts were designed with front panels that crossed over at the hem. A technique to help keep the shirt in place, Thomas Pink has brought this piece of tailoring ingenuity into the 21st century. With the right-sided panel curving under the left, the body remains concealed should the shirt ride up. Requiring skilled hands to make, it’s a rare feature in ready-to-wear shirts. For Thomas Pink, it comes as standard.

5. The Pink Signature Triangle Gusset

The gusset serves as the shirt’s anchor, reinforcing the seam. When you raise your arm, this triangular section holds everything in place. A signature feature since Thomas Pink was founded, this flash of pink looks simple but takes time and skill to perfect. Attached from beneath, it has to be stitched blind, with only the cutters’ skill to guide them.

6. The Split Yoke

A split yoke, the piece across the back of the shoulders, helps the shirt fit and sit better. Thomas Pink splits this piece in two cutting the cloth on the diagonal. This allows more natural stretch in the fabric to better accommodate the shoulders. A tradition of English shirtmaking, a split yoke is most noticeable on striped or patterned shirts. At Thomas Pink, the pattern has to match perfectly across the yoke but also where it meets the sleeves.

7. Pattern Matching

It’s the simplest test of a Thomas Pink shirt. Where stripes meet, they match. If patterns don’t match the overall effect can appear unbalanced. Thomas Pink matches patterns on the placket (the shirt’s centre and home to the buttonholes), as well as the gauntlet, the piece of fabric that lines and holds the sleeve opening. From shoulder to sleeve, Thomas Pink’s craftmanship is on full display; where the flat yoke meets the rounded sleeve we create as much harmony of stripes as possible. Lastly, under the collar where pattern matching is a point of pride, we go that little bit further – with carefully crafted pattern pieces specifically tailored to match patterns.

8. The French Seam

At Thomas Pink, we insist on intricate French seams for a strong hold and a smooth finish inside. Our shirts are sewn using 18 stitches per inch, the optimum number for quality and durability. We use single-needle lockstitches and, as a result, our shirts take about four times longer to construct than regular shirts. In fact, we actively ask our cutters to slow down, taking a bit more time to ensure finely turned hems. Examine your Thomas Pink shirt closely and you’ll see hand-stitching crafted with precision and care.

9. Off-Set Side Seam

Most shirts connect arm and body with one seam running through the armpit. Thomas Pink shirts use off-set side seams – one seam for the arm, another for the body, with both set separately. Off-set side seams help the shirt to sit smoothly as fabric doesn’t bunch at the back and any excess isn’t pulled round the front. It also prevents a build-up of fabric in the armpit as it spaces the connecting seams preventing them from being bulky. The intricacies required for an off-set side seam take around six times as much work as a regular one.

10. The Buttons

Thomas Pink uses sustainable mother of pearl buttons which are individually polished to remove any imperfections. If our shirts are built to last, so are our buttons. That’s why we use two procedures to secure each and every one. First, our buttons are lock-stitched onto the shirt. These stitches are then whipped and heat-sealed firmly in place. To the naked eye they appear little different, but this dual process makes our buttons extremely strong.